Difference between revisions of "H-34 Choctaw/Systems"

(→Throttle) |

(→Mixture Control Lever) |

||

| Line 131: | Line 131: | ||

===== Mixture Control Lever ===== | ===== Mixture Control Lever ===== | ||

| + | |||

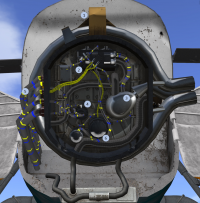

| + | [[File:S58-throttle.jpg|thumb|right | ||

| + | <figure id="fig:mixture"><caption> | ||

| + | Mixture and Carb. Heat Levers | ||

| + | </caption></figure>]] | ||

| + | |||

===== Carburetor Air Lever ===== | ===== Carburetor Air Lever ===== | ||

Revision as of 14:00, 29 June 2021

Contents

1 Helicopter

1.1 General

The Shergood H-34/S-58 is a piston engine helicopter designed for transportation of cargo and for search-and-rescue operations in day, night, visual and instrument conditions. The helicopter is powered by a 1,525 hp Wright R-1820-84 Cyclone rotary engine mounted in the nose of the aircraft. A drive shaft from the engine feeds diagonally up to the main transmission mounted under the main rotors. Fuel is carried by three cells on the belly of the aircraft. An entrance door is located on the forward right side of the main cabin with a hydraulic winch mounted over the door.

1.2 Gross Weight

The maximum gross weight is 13,300 pounds.

1.3 Pilot-Side Instrument Panel

| 1. DME | 2. RMI | 3. Attitude Indicator | 4. Tail-Number plate |

| 5. Airspeed Indicator | 6. Altimeter | 7. Radio Altimeter | 8. Checklist |

| 9. Fuel Indicator Selector | 10. Fuel Indicator Test | 11. Fuel Indicator | 12. Turn/Slip Indicator |

| 13. RPM Indicator | 14. Manifold Pressure | 15. HOBBS Time | 16. #2 VOR |

| 17. VSI | 18. #1 VOR | 19. 8-Day Clock | 20. Tail Wheel Lock |

1.4 Copilot-Side Instrument Panel

| 1. Tail-Number plate | 2. Airspeed Indicator | 3. Attitude Indicator | 4. RMI |

| 5. Airspeed Indicator | 6. Turn/Slip Indicator | 7. Altimeter | 8. 8-Day Clock |

| 9.Manifold Pressure | 10. VSI | 11. Radio Altimeter |

1.5 Center Instrument Panel

| 1. Pri. Hyd. Press | 2. Aux. Hyd. Press | 3. Main Trans. Oil Press | 4. Main Trans. Oil PrTr,ss |

| 5. Chip Indicator | 6. Main Switch Panel | 7. Checklist | 8. DC Volts/Amps |

| 9. Carburetor Temp. | 10. Cylinder Temp. | 11. Oil Temp/Press, Fuel Press | 12. UFH Radio |

| 13. Transponder | 14. Parking Brake |

1.6 Overhead Panel

The overhead panel includes various miscellaneous switches including most of the lighting controls, and controls for the hoist and heating systems.

2 Landing Gear System

The S-58 has a fixed landing gear system with two main wheels in the front and a tail wheel in the rear.

2.1 Parking Brake

A parking brake is located in front of the co-pilot seat under the center console (Item #14 in Figure 3). Activating the parking brake will increase resistance to ground movement. Click the handle to toggle its position, or use the chat command:

s brake

to toggle it.

2.2 Tailwheel Lock

A tailwheel lock is located on the pilot side below the pilot console. Click the handle to toggle its position, or use the chat command:

s taillock

to toggle it. The tailwheel lock should be used during rotor engagement to prevent the helicopter from turning on the ground during the high-torque stages of engagement.

3 Engines and Related Systems

The S-58 is powered by a 1,525 hp Wright R-1820-84 Cyclone, a 9-cylinder radial engine mounted in the nose of the aircraft (see Figure 5). A drive shaft oriented at 45 degrees passes through he main cabin up to the main transmission. The cylinders (see Figure 6) are arranged around the drive shaft of the engines at 40 degree intervals. Each cylinder has two spark plugs, each powered by a different engine driven magneto.

The engine compartment is accessed by two large doors at the nose of the aircraft. Engine accessories including the carburetor, dual magnetos, starter, and auxiliary hydraulic pump are mounted on the front of the engine.

3.1 Carburetor

A double-barrel, downdraft, injection-type carburetor is mounted at the entrance to the supercharger inlet.

3.1.1 Throttle

The throttle is controlled by a twist grip on the end of the pilot and copilot's collective. Clicking on the grip area of the collective will bring up a transparent overlay through which you can control the throttle (see Figure 7). The overlay has a large scale marked FULL and one end and CLOSED at the other. Clicking on this scale will move the throttle to that position. A small yellow triangle under the scale shows the current throttle position.

A smaller scale marked "TRIM" above the throttle scale can be used to make small throttle adjustments. Clicking left of the centerline will increase the throttle by an amount proportional to the distance from the centerline, while clicking to the right of the centerline will decrease the throttle by a proportional amount.

The gesture pack included with the aircraft also includes the following three gestures for controlling the throttle:

| Gesture | Description |

|---|---|

| r | Increase throttle |

| v | Decrease throttle |

| 0 | Close throttle |

The throttles are partially linked to the collective by a correlator which will increase throttle as the collective is pulled, and decrease throttle as the collective is lowered. In addition a throttle governor will engage above 2100 RPM to keep the engine, initially, at approximately 2500 RPM. Once the governor control is established, the pilot may change the governor setpoint by manually changing the throttle between 2100 and 2800 RPM. After a manual throttle change, the governor will reengage at the new RPM. To disengage the governor, roll the throttle below 2100 RPM.

3.1.2 Mixture Control Lever

3.1.3 Carburetor Air Lever

3.2 Ignition Systems

The ignition system consists of a dual magneto, an ignition harness carrying current to the spark plug on each cylinder, an induction vibrator, and an ignition switch. When the starter switch is depressed, and the ignition switch is in the R or BOTH position, the induction vibrator supplies current to the spark plugs for starting. Once the engine has started, current for the spark plugs is supplied by the engine-driven magnetos.

3.2.1 Ignition Switch

The ignition switch (see Figure 9) is located in the pilot's compartment on the main switch panel. Marked positions of the switch are: OFF, L, R and BOTH. The switch position may be selected by clicking on the marked position around the switch. When the switch is in the L position, the rear spark plugs of each cylinder are firing. When the switch is in the R position, the front spark plugs are firing, and when the switch is in the BOTH position, all spark plugs are firing.

3.3 Engine Priming System

The engine priming system is incorporated into the carburetor and consists of a two-point priming system controlled by a solenoid valve and an engine prime button. The priming system operates on DC current form the secondary bus. Fuel pressure for priming is supplied by the fuel boost pump.