Difference between revisions of "H-34 Choctaw/Normal Procedures"

(→Cruise) |

(→Cruise) |

||

| Line 197: | Line 197: | ||

|- | |- | ||

|rowspan="7"| 12,000 | |rowspan="7"| 12,000 | ||

| − | |12,000|| 2400 || 32.0 || 585 | + | |12,000|| 2400 || 32.0 || 585 || 230 || 128 || 25 |

|- | |- | ||

| − | |10,000|| 2500 || 32.0 || 568 | + | |10,000|| 2500 || 32.0 || 568 || 293 || 163 || 32 |

|- | |- | ||

| − | |8,000|| 2500 || 32.5 || 585 | + | |8,000|| 2500 || 32.5 || 585 || 309 || 172 || 34 |

|- | |- | ||

| − | |6,000|| 2500 || 32.4 || 515 | + | |6,000|| 2500 || 32.4 || 515 || 313 || 174 || 34 |

|- | |- | ||

| − | |4,000|| 2300 || 32.5 || 475 | + | |4,000|| 2300 || 32.5 || 475 || 356 || 198 || 39 |

|- | |- | ||

| − | |2,000|| 2300 || 33.1 || 740 | + | |2,000|| 2300 || 33.1 || 740 || 374 || 208 || 41 |

|- | |- | ||

| − | |SL|| 2200 || 32.4 || 420 | + | |SL|| 2200 || 32.4 || 420 || 394 || 219 || 43 |

|} | |} | ||

Revision as of 15:20, 7 July 2021

SECTION 6. NORMAL PROCEDURES

Contents

1 General

This section describes the procedures necessary to safely and efficiently operate your aircraft. A basic understanding of helicopter flight techniques is assumed.

2 Preflight Procedures

3 Normal Start-Up

3.1 Prestart

- Rotor Brake – ON

- Anti-collision lights – AS REQUIRED

- Cabin lights – AS REQUIRED

- All Light Rheostats - AS REQUIRED

- Cabin Heater Switch - OFF

- Fan Switch - OFF

- Pitot Heater Switch - OFF

- Windshield Wiper Rotary Switch - OFF

- Crew Alarm Bell - TEST

- Hoist Master Switch - OFF

- Radio Master Switch - RADIO MASTER

- Circuit Breakers - IN

- Stick Trim Switch – ON

- Fuel Shutoff Valve - Open

- Mixture Control Lever - IDLE CUT-OFF

- Carburetor Air Lever - DIRECT

- Clutch Pump Switch - OFF

- Servo Switch – ON

- Parking Brake Handle - RESET

- Tail Wheel - LOCKED

- Radios, Radar Altimeter, IFF - OFF

- Ignition Switch - OFF

- Fuel Booster Pump Switch - OFF

- External Power - ON (voltage checked)

- Battery-Generator Switch - BATT ONLY (voltage checked)

Note: When starting without external power, the battery-generator switch must be in the BATT ONLY position to energize the starter relay and engine primer which are connected to the secondary bus. - Fuel Pressure – Check

- Fuel Shut-Off Switch - CLOSED

- Fuel Pressure Gage - ZERO PSI

- Fuel Shut-Off Switch - OPEN

- Fuel Pressure Gage - Check for Fuel Pressure Increase

- Fuel Booster Switch- FUEL BSTR PUMP

- Clutch Pump Warning Light - TEST

- Instr. Pwr. Failure Warning Lights - TEST

- Fuel Low Level Warning Light - TEST

- Rotor Brake Warning Light - TEST

- Generator Warning Light - TEST

- Collective - DOWN

- Throttle – CLOSED

3.2 Starting Engine

- Starter Button – DEPRESS

- Ignition Switch – BOTH (after engine has cranked for approximately 5 sec.)

- Primer Button – DEPRESS

NOTE: If engine fails to start after 30 seconds, allow the starter to cool and then repeat starting procedure - Mixture Control Lever – RICH

- Engine – Verify running smoothly

NOTE: Do not allow the engine to exceed 1400 RPM on starting.

CAUTION: To prevent possible engine damage, if oil pressure does not register within 10 sec. or reach 40psi within 20 sec., stop engine and investigate. - Starter and Primer – OFF

- Idle Engine at 1000 +- 100 rpm until oil pressure has stabilized

- Aux. Hyd. Press. - 1300 to 1600 psi

3.3 Post-Start

- Oil Pressure – CHECK

- Ignition Switch – CHECK

Idle engine at 1000 +- 100 rpm. Turn switch OFF momentarily to see if engine stops firing. Return switch to BOTH. - Throttle – 1400 RPM

as soon as engine runs smoothly on RICH MIXTURE and oil pressure has stabilized. - Flight Control Servo – AUX OFF

- Check that auxiliary servo hydraulic pressure remains constant.

- Check controls for free and easy movement.

NOTE: The auxiliary servo hydraulic system should not shut off when the switch is placed in the AUX OFF position, as there is no pressure in the primary servo hydraulic system until after clutch engagement.

- Flight Control Switch – ON

- Carburetor Air Lever – DIRECT

- Manifold Pressure Drain Valve – PRESS

- Fuel Gage Test Switch – TEST

- Fuel Quantity Selector – CHECK ALL

Rotate through the four positions, TOT, FWD, CTR, AFT, to check fuel quantity in each tank. Leave switch at FWD position. - Engine temp. and press. – CHECK

3.4 Engage

- Oil Temp – >40C

- Rotor Brake Lever - OFF

- Rotor Brake Warning Light – OFF

- Collective Pitch Stick – MINIMUM PITCH

- Cyclic Control Stick – CENTERED

- Tail Rotor Control Pedals – CENTERED

- Throttle – 1700 Engine RPM

- Clutch Switch – CLUTCH

Verify clutch switch warning light - ON - Throttle – Increase to 2000 to 2400 engine rpm to produce 1525 apparent rotor rpm

- Apparent Rotor Speed – 1525 RPM

- Engine – cut quickly to below rotor speed, then increase to match needles

Note: Do not let apparent rotor RPM fall below 1200 RPM or mechanical coupling will not engage.

Note: As throttle is increased, the rotor and engine tachometer needles should line up, indicating that the clutch mechanical coupling has engaged. - Clutch Switch – OFF

- Clutch Warning Light – Verify OFF

- Trans. Temp. and Press – CHECK

- Engine – 2000 RPM

- Pri. Hyd. Press. - 1300 to 1600psi

3.5 Post-Engage

- Battery-Generator Switch - BATT & GEN

- External Power – OFF

- Radios, Radar Altimeter, IFF – ON

- Instrument Power Switch – No 2 INV

- INST PWR FAIL light – Verify OFF

- Instrument Power Switch – No 1 INV

- Flight Instruments - Check

- Engine Driven Fuel Pump Check

- Fuel Booster Pump Switch – OFF

NOTE: A drop of approximately 10 amps should result indicating that the fuel booster pump is shut off. Engine should remain running on engine driven pump. - Fuel Pressure Gage - 22 1/2 to 23 1/2 psi

- Fuel Booster Pump Switch – ON

- Fuel Booster Pump Switch – OFF

- Warning Lights – OFF

- Hydraulic Hoist – CHECK

- Hoist Master Switch – PILOT

- Hoist Switch – DN, OFF, UP

- Hoist Master Switch OFF

- Servo Checks

- Flight Control Servo - PRI OFF

- Pri. Hyd. Press – Verify 0 psi

- Flight Control Servo – ON

- Pri. Hyd. Press – Verify normal psi

- Flight Control Servo - AUX OFF

- Aux. Hyd. Press – Verify 0 psi

- Flight Control Servo – ON

- Aux. Hyd. Press – Verify normal psi

- Mixture Check

- Mixture Control Lever – NORMAL

- Engine – Verify normal operation

- Mixture Control Lever - RICH

- Ignition System Check

- Engine – 2200 RPM

- Ignition – R then L (max drop 75 RPM)

- Ignition – BOTH

- Freewheeling Unit Check

- Engine – 2200 RPM

- Cut throttle rapidly – verify RPM split

- Engine – 2200 RPM

4 Pre-Taxi Check

5 Takeoff and Climb

5.1 Takeoff

5.2 Climb

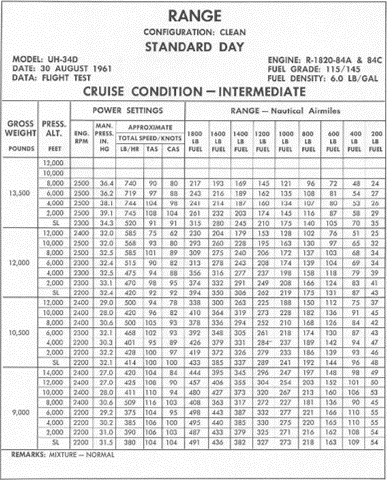

6 Cruise

| GROSS WEIGHT POUNDS |

PRESS ALT FEET |

POWER SETTINGS | RANGE - Nautical Miles | ||||||||||

| ENG RPM |

MAN PRESS |

LB/HR | 1800 LB FUEL |

1000 LB FUEL |

200 LB FUEL | ||||||||

| 13,500 | 12,000 | ||||||||||||

| 10,000 | |||||||||||||

| 8,000 | 2500 | 36.4 | 740 | 217 | 121 | 24 | |||||||

| 6,000 | 2500 | 36.2 | 719 | 243 | 135 | 27 | |||||||

| 4,000 | 2500 | 38.1 | 744 | 141 | 134 | 26 | |||||||

| 2,000 | 2500 | 39.1 | 745 | 261 | 145 | 29 | |||||||

| SL | 2300 | 34.3 | 520 | 315 | 175 | 35 | |||||||

| 12,000 | 12,000 | 2400 | 32.0 | 585 | 230 | 128 | 25 | ||||||

| 10,000 | 2500 | 32.0 | 568 | 293 | 163 | 32 | |||||||

| 8,000 | 2500 | 32.5 | 585 | 309 | 172 | 34 | |||||||

| 6,000 | 2500 | 32.4 | 515 | 313 | 174 | 34 | |||||||

| 4,000 | 2300 | 32.5 | 475 | 356 | 198 | 39 | |||||||

| 2,000 | 2300 | 33.1 | 740 | 374 | 208 | 41 | |||||||

| SL | 2200 | 32.4 | 420 | 394 | 219 | 43 | |||||||